Apple to invest $3.6 billion in Kia Motors to build an Apple Car

Apple is planning to invest $3.6 billion in Kia Motors as they collaborate to build an electric car reports South Korea’s online news outlet DongA.com

The report said the deal would be signed on February 17. Apple will aim to produce 100,000 vehicles annually by 2024 at the Kia plant according to the report and aims to expand that annual capacity to 400,000 at a later stage.

Following the report, Kia Corp shares surged to their highest in over two decades. Apple’s funds will be used to build exclusive facilities for the production and development of Apple Car.

The iPhone maker’s automotive efforts, known as Project Titan, have proceeded unevenly since 2014 when it first started to design its own vehicle from scratch. At one point, Apple drew back the effort to focus on software and reassessed its goals. Doug Field, an Apple veteran who had worked at Tesla, returned to oversee the project in 2018 and laid off 190 people from the team in 2019.

Central to Apple’s strategy is a new battery design that could “radically” reduce the cost of batteries and increase the vehicle’s range, according to a third person who has seen Apple’s battery design.

The car will reportedly have more than 300 miles of range on a full charge and should get 60 miles on a five-minute charge. It will also be able to go from 0-60 mph in less than 3.5 seconds and have a top speed of 160 mph reported Apple analyst Ming-Chi Kuo.

However, these specs according to Kuo are for the high-performance model which means a cheaper, regular model will also be available.

Apple’s car might feature multiple lidar sensors for scanning different distances, another person said. Some sensors could be derived from Apple’s internally developed lidar units, that person said. Apple’s iPhone 12 Pro and iPad Pro models released this year both feature lidar sensors.

Reuters had previously reported that Apple had held talks with potential lidar suppliers, but it was also examining building its own sensor.

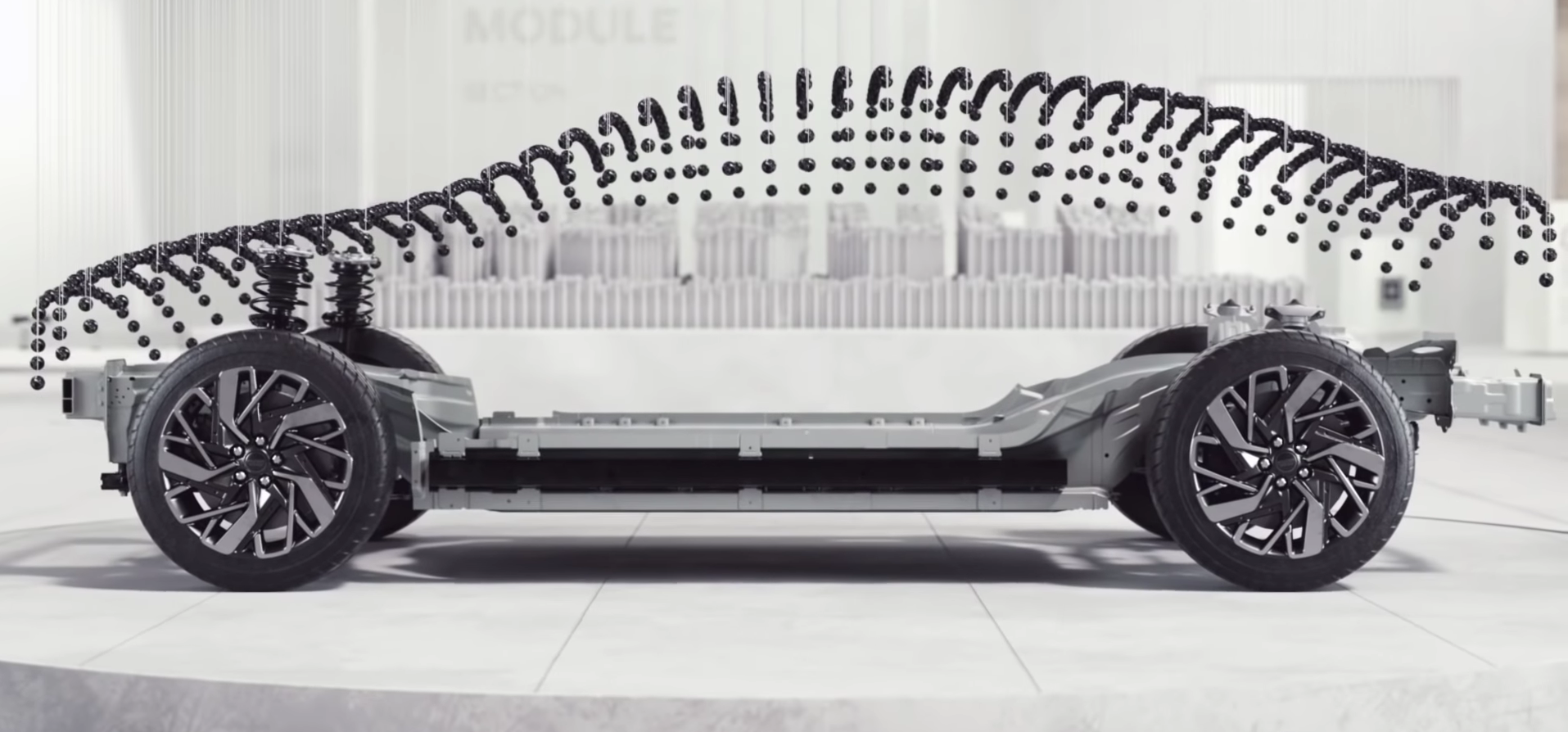

As for the car’s battery, the company plans to use a unique “monocell” design that bulks up the individual cells in the battery and frees up space inside the battery pack by eliminating pouches and modules that hold battery materials, one of the people said.

Apple’s design means that more active material can be packed inside the battery, giving the car a potentially longer range. Apple is also examining chemistry for the battery called LFP, or lithium iron phosphate, the person said, which is inherently less likely to overheat and is thus safer than other types of lithium-ion batteries.

Making a vehicle represents a supply chain challenge even for Apple, a company with deep pockets that makes hundreds of millions of electronics products each year with parts from around the world, but has never made a car. It took Elon Musk’s Tesla 17 years before it finally turned a sustained profit making cars.

“If there is one company on the planet that has the resources to do that, it’s probably Apple. But at the same time, it’s not a cellphone,” said a person who worked on Project Titan.